The recycling industry plays a crucial role in processing and minimizing waste while promoting sustainability. Conveyors play a vital role in recycling operations, facilitating the movement, sorting, and separation of materials. Just like in other sectors, conveyor belts used in recycling must endure rough handling and operate with efficiency, reliability, and safety. In the world of recycling, significant amounts of metal and other sharp materials such as wood are processed with nails. To ensure that the production process is interrupted as little as possible by maintenance, it is crucial that conveyor belts are wear-resistant and have a long service life. In this way, machine downtime is kept to a minimum. Furthermore, there are additional specific requirements applicable to this industry. We have compiled a list of these features for your reference.

Efficient and durable

Conveyor belts used in recycling processes must withstand demanding conditions and heavy workloads associated with this sector. Here are some key features that recycling conveyor belts should possess:

- Adaptability: Recycling conveyor belts should be able to accommodate various recycling processes and materials. This requires flexibility in terms of width, length, gradient, and speed.

- Separation Technology: Advanced separation technologies, such as magnetic systems for metals, optical sensors for plastics, or air currents for lightweight materials, can be integrated into recycling conveyors to effectively separate different material types.

Besides a hard coating, the recycling industry also requires conveyor belts that are resistant to oil, grease, chemicals and capable of moving heavy loads.

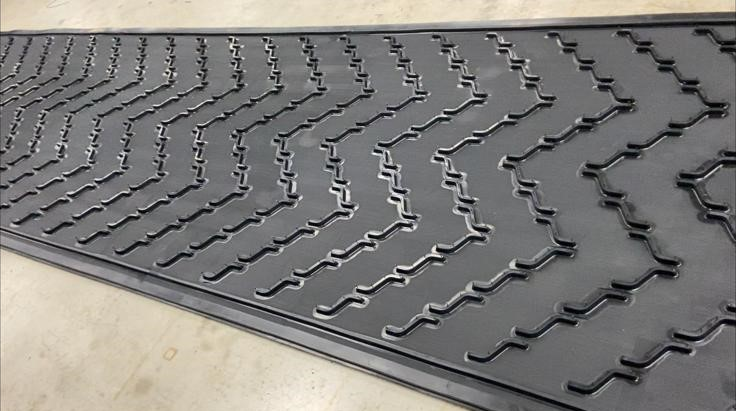

Chevron conveyor belts

Rubber chevron conveyor belts are a specific type of conveyor belt used for transporting bulk materials, such as grains, pebbles, stones, and other similar materials with a tendency to roll away or shift during transport. These conveyor belts are designed with a unique profile on the rubber tread, which resembles a row of zigzag patterns, similar to the shape of a chevron, hence the name.

Here are some features and benefits of rubber chevron conveyor belts:

- Enhanced grip: The chevron profile on conveyor belts provides enhanced grip on the material being transported. This is especially useful when moving materials on slopes or transporting heavy loads uphill.

- Prevents spillage: The design of the chevron profiles helps prevent materials from sliding or spilling off the conveyor belt, minimising waste and increasing efficiency.

- Various applications: Rubber chevron conveyor belts are often used in industrial sectors such as agriculture, mining, quarrying, construction and recycling, where they help move materials across different types of terrain and under different conditions.

- Durability: These conveyor belts are made of high-quality rubber materials that are resistant to wear and tear, resulting in a longer service life and lower maintenance costs.

- Adaptability: Rubber chevron conveyor belts can be adapted to specific transport needs with regard to width, length, slopes and material capacity.

- Efficiency: By increasing grip and reducing spillage, chevron conveyor belts contribute to a more efficient conveying process and reduce the risk of disruptions in production.

It is important to note that the right type of conveyor belt depends on the specific requirements of an application. Chevron conveyors are ideal for situations where materials need to be moved over uneven terrain or when transporting loads uphill, but there are also other types of conveyors available that are suitable for different purposes, such as flat conveyors for moving flat loads and goods. Read more about our various types of chevron belts here.

Special profiles for conveyors the recycling industry

Our latest innovation, the G Profile, has been specifically designed to enhance efficiency and sustainability in recycling processes. With its unique shape, this profile minimises material loss and preserves the integrity of the conveyor belt. The improved grip ensures effective conveyance, reducing waste and extending the lifespan of the belt.

The G Profile is produced using a special hot vulcanisation process, ensuring seamless integration with the conveyor belt and eliminating the risk of profile detachment. Furthermore, its design allows for adjustable angles, making it suitable for challenging locations and enabling efficient transportation.

In addition to its versatility, the G Profile exhibits exceptional durability and resistance to deterioration and cracks. These features make it particularly advantageous in the recycling industry, where heavy materials are frequently handled. By utilising the G Profile, recycling operations can achieve enhanced performance and contribute to sustainable waste management practices.

Furthermore, we provide a range of other profiles to cater to various needs:

- Single V profile: primarily designed for mobile installations, featuring a profile height of 17 mm. It is available in belt widths ranging from 400 to 1,400 mm.

- Double V profile: suitable for both stationary and mobile installations, also with a profile height of 17 mm. It is offered in belt widths ranging from 1,400 to 2,200 mm.

- Triple V profile: mainly intended for stationary installations, featuring a profile height of 17 mm. It is available in belt widths ranging from 2,000 to 2,400 mm.

Tailor-made conveyor belts for recycling

LBS offers tailor-made conveyor belts specifically designed for recycling applications. Our priority is to achieve utmost customer satisfaction by adopting a flexible, proactive, and customer-centric approach. We strongly believe in the power of collaboration, whether it involves product variations or addressing unique requirements. Our goal is to work together with you to create the perfect conveyor belt that aligns seamlessly with your company, work processes, and operational conditions.

Whether you require top-quality conveyor belts for recycling or any other production or business process Feel free to contact us without any obligation, we look forward to hearing from you.