OPTIMIZE YOUR RECYCLING PROCESS WITH THE NEW G PROFILE

OPTIMIZE YOUR RECYCLING PROCESS WITH THE NEW G PROFILE

In the world of recycling, efficiency and sustainability are of paramount importance. That is why we at LBS have proudly developed our modular G profile, designed specifically for our valued customers in the recycling industry. Whether in mobile or stationary installations, our new G profile offers a range of benefits that take conveyor performance to new heights.

DESIGN FOR DURABILITY AND EFFICIENCY

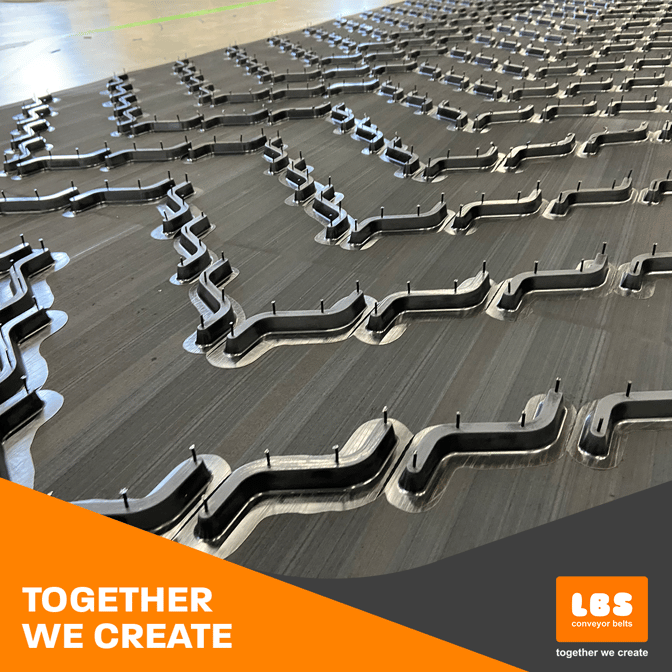

Our innovative G profile is not just another profile on a conveyor belt. It is an optimized distribution that transports heavy materials, such as metals and stones, smoothly and efficiently. The result? A conveyor belt with a significantly longer service life and improved tool life. Together with our customers, we create the optimal conveyor belt that makes a significant difference in production performance.

UNIQUE PROFILE FOR REDUCED WEAR

The G profile is designed with a unique shape aimed at reducing material loss and wear on the conveyor belt. With single V, double V and triple V shapes, the profile spreads material evenly across the belt width. This results in a better grip on the material being conveyed and minimizes waste. No more central accumulation in the center of the conveyor belt; instead, the material is gradually distributed across the entire width, reducing wear and significantly extending the life of the conveyor belt.

ADVANTAGES OF THE NEW G PROFILE OVER A STANDARD CHEVRON PROFILE

Through our years of experience, we have not only accumulated knowledge but also developed the G profile with several advantages:

- Shortened pitch from 330 mm to 250 mm for higher capacity.

- Double V & Triple V profile for improved product spread and reduced wear.

- Up to 2,400 mm belt width!

- Improved support return on carrier rollers due to improved profile turnover.

- Profile available on numerous belt constructions!

WE OFFER MORE THAN THE STANDARD CHEVRON PROFILE

'Standard' chevron profile is extremely suitable for various industries and applications. We see in the recycling industry working with coarse materials that the G profile shows reduced wear. Because the design of this chevron profile has been considered with the customer and industry, there is an optimal distribution of the product which ensures that the customer can enjoy a longer life of the conveyor belt and significantly less product loss. Our G profile has been a reliable part of various recycling plants for quite some time now.

TOGETHER WE CREATE CUSTOMIZED SOLUTIONS

At LBS, we specialize in the production of conveyor belts and related products. In addition to our new G Profile, we offer custom-made conveyor belts, as well as a wide range of parts such as trough sets, scrapers, sidewalls and longitudal edges and guide ropes and strips. Our modern machinery and equipment enable us to provide solutions that meet your specific needs.

Want to read more about our G profile and what the possibilities are in this special chevron profile?

DOWNLOAD THE FULL BROCHURE ABOUT OUR G PROFILE AND WHAT THE BENEFITS AND APPLICATIONS ARE HERE.

Together we create

At LBS we strive for 100% customer satisfaction and work closely with our customers to provide customized solutions. Do you have questions about our new G Profile or other conveyor related issues? Please do not hesitate to contact us. Our specialists are ready to help you optimize your recycling process.

Providing our customers with optimally performing conveyor belts is our mission. However, we do not only produce and supply conveyor belts, but you can also contact us for service, maintenance and spare parts.

Are you looking for the most suitable conveyor belt for your installation? Do you have other questions about our products and services? Contact us!

.png?width=672&height=672&name=G-Profiel%20-%20Mockup%20(los).png)