PROTECTION FOR DELICATE PRODUCTS: DISCOVER THE TO-cleats!

Have you ever worried about transporting delicate products such as vegetables, potatoes or fruit? You may have noticed that traditional cleats do not always meet the requirements of your precious goods. But don't worry, because we have a solution specially designed to protect your products and minimise damage: our brand new TO-cleats!

PREVENT DAMAGE AND BRUISING: TO-cleats FOR YOUR PRODUCTS!

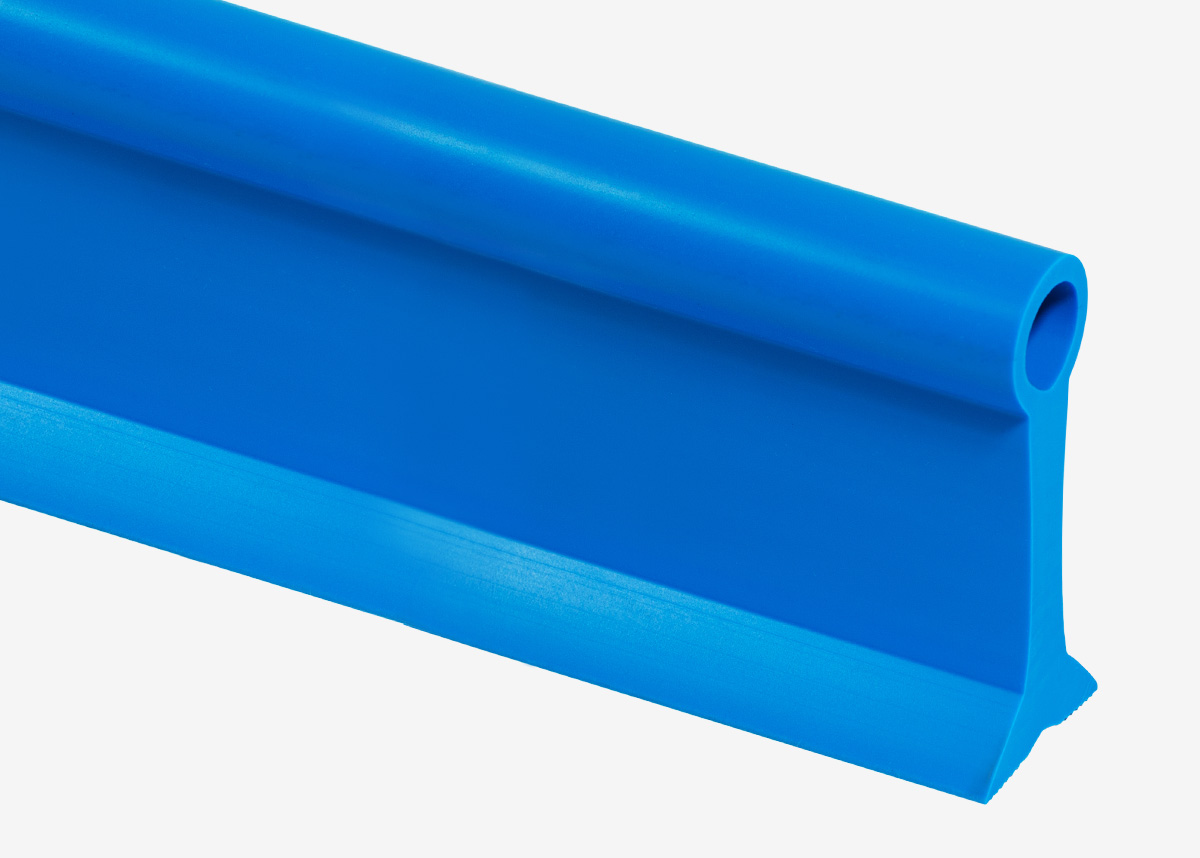

If you are looking for a way to ensure your products arrive at their destination safely and undamaged, our TO-cleats is just what you need. It is designed with a rounded top and a hollow space, landing your products more gently and reducing the risk of damage.

DURABILITY AND FUNCTIONALITY COMBINED

One of the main advantages of our TO cleat is its unique round ‘bubble’ top. Unlike standard straight-top cleats, which often result in bruises and dark spots on fruit and potatoes, for example, the soft landing on our TO cleats ensures that your produce remains intact.

This innovative approach to transport reliability is a game-changer for companies that value the quality and presentation of their produce. Whether you are a fruit and vegetable supplier, a potato processor or a supermarket offering fresh produce, our TO-cleats offers the perfect solution to minimise damage and maximise customer satisfaction.

In short, our new TO cleats are a must-have for anyone involved in transporting delicate produce. With its innovative design and focus on quality and durability, it is the perfect choice to ensure your goods arrive safely and in top condition, time after time.

So what are you waiting for? Upgrade to our TO-cleats today and protect your products like never before!

Contact us today to learn more about our TO cleats, our products and services or any other conveyor belts. Get in touch with us!

.png?width=681&height=227&name=Mail%20header%20TO-meenemer%20(EN).png)