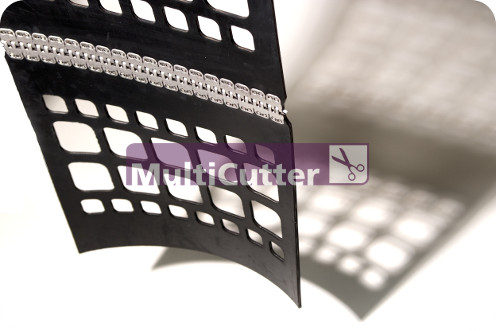

Our MultiCutter offers you the latest “cutting edge” technology, allowing us to supply custom-made conveyor belts and sheets. Our fully automated and state-of-the art MultiCutter enables you to contract out your manual work. We are able to cut all kinds of materials from the thinnest synthetics to the thickest polyurethane plates and steel reinforced rubber conveyor belts. Just imagine: no more stock nor manual work and just-in-time deliveries! In cooperation with you

we will compose the best fitting product. We have our work cut out for us. Allow us to deliver your custom-made products just-in-time so that you can mount them easily and carefree.

Would you like more information?

Leave your e-mail address below.

FEATURES AND CHARACTERISTICS OF THE MULTICUTTER

The MultiCutter is suitable for production of both large and small series. A prototype can also be

made if required. Our working method is simple: you supply the specifi cations of your product in DXF or DWG format. With the aid of this drawing, the MultiCutter can accurately reproduce any

required shape. The cut product will therefore comply with your specifi cations, including any

perforations, notches, recesses, grooves etc. Quick, effi cient and accurate!

benefits of the multicutter

» No manual work

» Machining (2D) operation

» Quick & efficient

» Accurate according to drawing

» Any shape or dimension can be cut

» Small and big series

» 100% reproducibility

» Rapid prototyping

» Reduced material costs

» Limited cutting waste

» Just-In-Time

applications off the multicutter

» Rubber and synthetic screens

» Synthetic and rubber side skirting

» Curve conveyor belts

» Fall breaker chutes

» Protection sheets

» Gaskets and seals

» Shotblasting curtains

» Snow- and stable ploughs

materials cut on the multicutter

» Rubber, with or without fabric inlays

» Synhtetics, with or without fabric inlays

» Polyurethane

» HMPE

» Silicons

» Teflon

» Foam

» Cellular rubber

about LBS conveyor belts

LBS is your specialist for conveyor belts and related products. We design and make customised conveyor belts for various applications and sectors. With our dedication, experience, modern machinery and equipment, we achieve high-quality customised solutions.

Quality always comes first for us, which is why we only work with quality materials. We aim for the highest possible customer satisfaction and we do this by listening carefully and working closely with our customers.

ask for the possibilities

Interested? Send us a digital file of your product (info@lbs.cc). The product will be manufactured on the MultiCutter, so that you can decide for yourself whether the MultiCutter is cut out for your product. For more information about the MultiCutter, you can of course contact one of our sales staff (telephone +31 591 668220).

LBS not only manufactures and supplies conveyor belts, but you can also come to us for service, maintenance and spare parts. On our page about the MultiCutter you can read more about this machine.

Are you looking for a suitable solution for your conveyor belt problem? Do you have questions about our MultiCutter or other questions about our products and services? Please contact us!