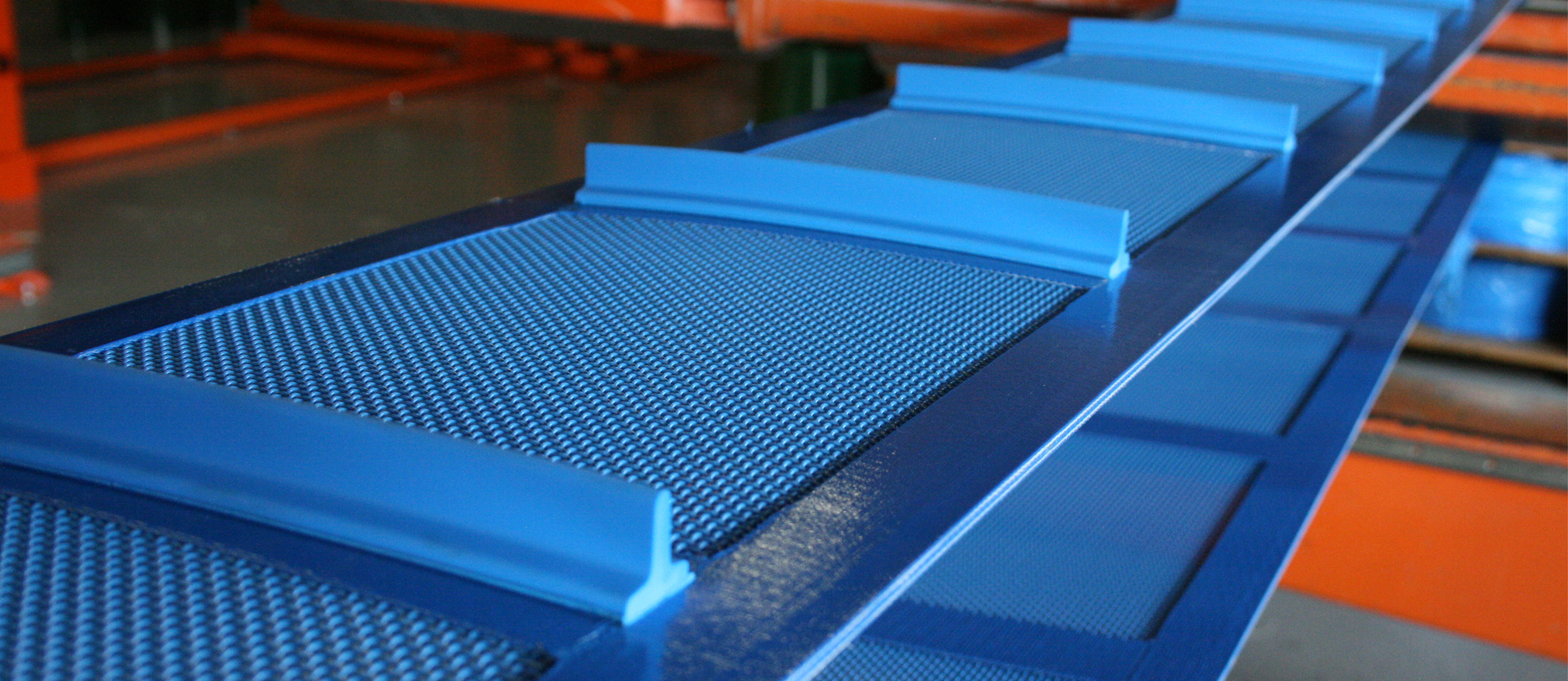

Synthetic gauze belts are widely used in the food industry because of their unique properties and application possibilities. They have an open structure that allows air circulation and liquid drainage, making them suitable for different processes and environments.

APPLICATIONS OF gauze BELTS

Here are some of the main applications of gauze belts in the food industry:

1. Baking processes: Gauze belts are commonly used in bakeries for baking bread, pastries, biscuits and other bakery products. The open structure of mesh belts ensures even heat distribution, resulting in uniformly baked products.

2. Chilling and freezing processes: Gauze belts are used to transport food products through chilling and freezing environments. Air circulation prevents condensation and promotes even cooling or freezing.

3. Frying and baking: In food processing facilities where food is fried or baked, gauze belts can be used to transport food products through the frying or baking process.

4. Dewatering and draining: Gauze belts are used to remove excess moisture from food products, such as draining oil after deep-frying snacks.

5. Washing and cleaning: Gauze belts can be used for washing and cleaning food products, where water and cleaning fluids can be drained off.

6. Sterilisation and pasteurisation: In processes where food products are sterilised or pasteurised, gauze belts can be used to transport the products through the process while steam or heat is evenly distributed.

7. Decoration and glazing: When applying decorations, glazes or coatings to food products, gauze belts can help ensure even application.

8. Food inspection: Gauze belts can be used in conjunction with food inspection systems, such as X-ray machines, to transport and inspect food products for contaminants and abnormalities.

9. Product processing and handling: Gauze belts can be used for general product processing and handling, such as transporting vegetables, fruit and other food products between different production stages.

Hygiene en gauze belts

The versatility of Gauze belts makes them suitable for a wide range of applications in the food industry, helping to optimise production processes, maintain quality standards and comply with hygiene regulations.

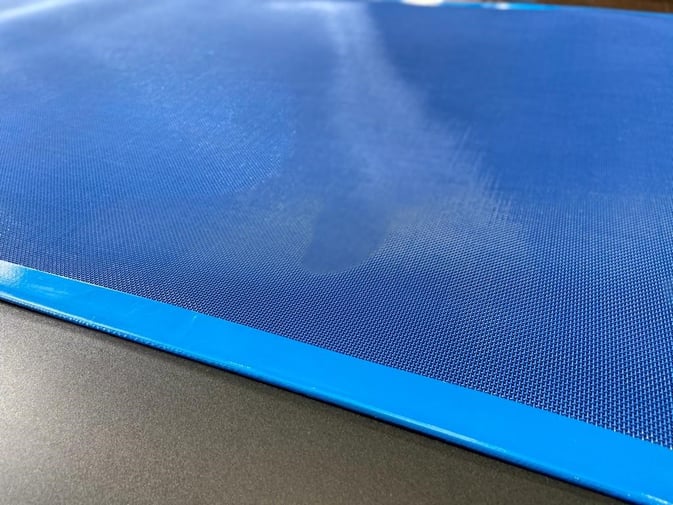

Gauze belts can also be equipped with closed sides. This procedure involves applying a layer of PVC or PU to the edges of the conveyor belt, shielding the open fabric from dirt, water and grease. This adaptation is mainly used in the food industry to ensure hygiene, as moisture and dirt cannot penetrate the fabric, minimising the risk of shrinkage. Moreover, it extends the life of the conveyor belt.

Besides Gauze belts, we also offer a wide range of other types and types of conveyor belts. On our synthetic conveyor belts page, you can view many more synthetic conveyor belts.

QUESTIONS? Get in touch!

LBS is committed to quality and only works with high-quality materials and components. In doing so, we strive for the highest possible customer satisfaction and work closely with our clients. With a flexible and proactive approach, we meet our clients' specific needs as much as possible.