THE INTRIGUING FUNCTIONALITY OF BUNKER CONVEYORS

In the modern world of industry and manufacturing, conveyor belts play a crucial role in efficiently and effectively moving materials from one location to another. One particularly fascinating type of conveyor is the bunker conveyor, which is an essential link in numerous industries, ranging from agriculture to mining and everything in between. In this blog, we dive deeper into the functionality of bunker conveyors and how they contribute to different industries.

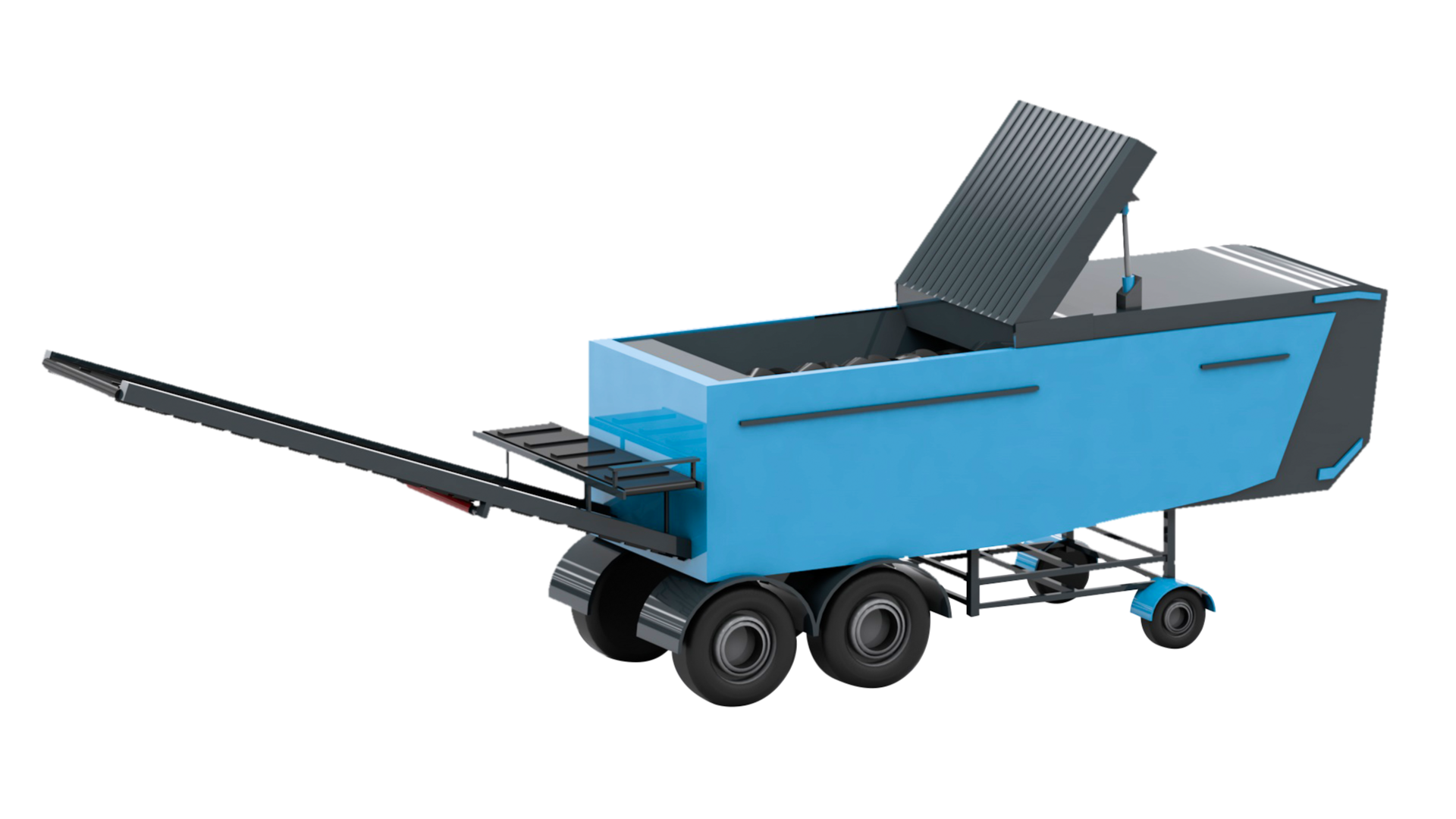

What is a bunker conveyor belt?

A bunker conveyor belt, also known as a hopper conveyor, is a type of conveyor specifically designed to store and gradually feed materials for further processing or transport. The essence of a bunker conveyor is the funnel-shaped structure at the beginning, the "bunker", in which materials can be temporarily stored before being fed to the main conveyor. This temporary storage makes it possible to maintain a constant and controlled supply of materials, even if the supply source is irregular.

Applications of bunker conveyor belts

Building and construction: In the construction industry, bunker conveyor belts are often used to transport materials such as sand, gravel and rubble from trucks to building sites. The bunker function ensures a steady flow of materials, so the construction process is not delayed by irregular supply.

Agriculture: Bunker conveyor belts are invaluable in the agricultural sector, where they are used to move crops such as grain and potatoes from the field to storage facilities. The funnel-shaped bunker ensures that harvested crops are evenly distributed on the conveyor, preventing damage and increasing efficiency.

Mining: In the mining industry, bunker conveyor belts are used to transport ores and minerals from mine sites to processing facilities. The storage function allows miners to collect large quantities of material before it is processed, optimising the process and enabling a continuous flow of raw materials.

Advantages of bunker conveyor belts

Continuous feeding: The funnel-shaped bunker allows continuous and even feeding of materials, even when the source of material is irregular. This minimises downtime and increases the efficiency of operational processes.

Protection of materials: Storing materials in the bunker ensures that they are not directly exposed to weather conditions or possible damage during transport. This helps maintain the quality and integrity of materials.

Efficiency: Bunker conveyor belts reduce the need for manual intervention to feed materials, which minimises human error and increases overall efficiency.

Processing optimisation: In industries such as agriculture and mining, the gradual feeding of bunker conveyor belts allows better control over the further processing process, improving the quality of the final product.

VERSATILITY OF BUNKER CONVEYOR beltS

Bunker conveyor belts play a vital role in various industries due to their unique ability to store and gradually feed materials for further processing or transportation. This functionality results in continuous feeding, protection of materials, improved efficiency and optimisation of handling processes. Whether in construction, agriculture, mining or other sectors, bunker conveyors remain an indispensable link in the chain of industrial activities, enabling companies to keep running smoothly and deliver high-quality products.

We supply conveyors based on quality, robustness and durability. You can also come to us for advice, for example on the correct assembly and loading of conveyor belts, for optimal running.

Do you have questions about this or other questions about conveyor belts? Contact us, our specialists are ready to assist you.